Dry-Offset printing

The UV Dry-Offset printing, also called waterless, is a process where the relief surface of the photopolymer transfers the ink on a blanket and subsequently the inked image on a substrate, such as the polypropylene containers.

UV Dry-Offset printing advantages

• Significant quality/price ratio, with reduction in operating costs, no risk of returns and waste

• Excellent print quality, high definition, color brilliance, good gloss and simple profiling

• Fast printing cycle, quick curing and absorption

• Print stability for the entire print run and on the full printed area, especially in application fields where minimum tolerances are accepted on variations in print density and color shades, such as pharmaceuticals or cosmetics

Main applications

Printing on metal cans, plastic tubes, yogurt jars, caps and cylindrical containers in general.

The use of a wide range of materials as paper, cardboard and non-absorbent (eg plastics as PVC, PC, PS, ABS, PET) in commercial printing, packaging and labels is a real challenge for entrepreneurs. Above all, plastic films are increasingly in demand. This segment previously reserved exclusively for screen printing, is now also accessible to offset printing thanks to UV Dry-Offset technology.

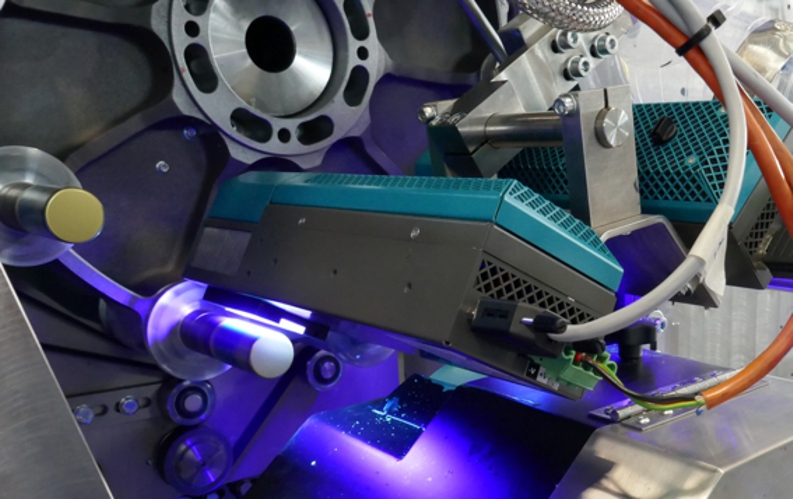

UV Dry-Offset Print and UV LED technology

DROLED UV LED lamps allow UV curing of inks in dry-offset printing, combining the advantages of this type of printing with all the advantages of UV LED technology:

- Reduction of energy consumption and specific adjustment of UV emission

- Immediate lamps on/off

- No overheating on the substrate to be printed

- Lamp life 20-30,000 hours with no perceptible decay

- No ozone